Industry-Sponsored Student Capstone Projects

2021/2022

In the 2021/22 academic year the industry capstone program was supported by 62 sponsors and 95 real-world projects. Over four hundred students from across the College of Engineering participated. Scroll down to learn more about each project.Access Laser

Automatic Load-Pull Tuner

This student team worked to build an automated load-pull tuner, a tool used for the RF engineers to characterize new transistors and test the performance of newly designed radio frequency (RF) Power-Amplifiers. The team designed a circuit (delivering the PCBA) with a control firmware and a graphical user interface (GUI) to acquire the required data and save them in the computer. The combination of PCBA, firmware, and GUI enables RF Engineers to deliver pulses, change the load to the amplifier, and acquire test data from an oscilloscope for their design analysis.

adidas

Natural Language Inputs in 3D Printed Footwear Components

Last year, a capstone team worked with adidas on their line of 3D printed mid-soles. This year's team continued their work to create an understanding of common language used by running footwear consumers and translate this language into the engineering space. The team gathered information about language use from athlete-consumers directly and linked this language to commonly 'found' objects (i.e.: sponges, foam rollers, bouncy balls). The team then designed and printed sample pucks around these consumer findings that are able to be stepped onto to mimic the midsole of a shoe. The capstone team used a software program to change aspects of the shoe, then printed (using UW's Carbon DLS printer) and tested the designs.

AeroVironment

Capabilities for Deployable Multirotor UAVs from the AV Puma LE

This student team redesigned the airframe of a multirotor so it can fit two vehicles inside the same space. Each vehicle can be deployed independently and fly for 10 minutes providing video back to the operator. When components need to be folded on the airframe, the components deploy and the air vehicle regains control. The team used a tablet/smartphone to control the vehicle via LTE. The team used a Puma surrogate vehicle to design/modify the deployment of the multirotors to ensure the multirotor can recover from a tumbling condition and fly a mission safely with the LTE link prior to attempting with the surrogate vehicle.

Alaska Center for Energy and Power (ACEP)

Synthetic Network for the Alaska "RainBelt" Electric Power System

The student team developed publicly accessible Alaska-based power system models and associated load and generation data representing seasonal and futuristic scenarios. The model and data is shared via GitHub and the BetterGrids repository, and is reproducible through code or documentation. Prior to this project, Alaska and Alaskan generation or load data were excluded from existing power system models, which are essential for assessing operations and planning of electric grids, including power systems' stability and future generation and load scenarios.

All Wheels Up

A Wheelchair Spot - Roadmap to Accessible Air Travel

Currently there is no wheelchair spot on airplanes, just as before 1990 there were no wheelchair accessible buses. It took 14 years for buses to become accessible. With the R&D and all the key stakeholders aligned, a wheelchair spot on planes is possible. The biggest question is how do we get from where we are today to implementation? The largest hurdles are that there are no standards for crash testing wheelchairs, there are no wheelchairs or wheelchair securement systems currently developed or manufactured to FAA standards (as they do not exist). This student team completed a step by step easy to understand guide for multiple industries on how to get from today with no wheelchair spot on planes, no standards, and no R&D started, to the point of certification and implementation.

All Wheels Up

Financial Incentives for Wheelchair Accessible Airplanes

This student team created a budget impact model that shows that a wheelchair spot on a plane should not be perceived as an expense and loss of revenue due to one less seat in the cabin, but instead could be a cost savings. To accomplish this the team explored a number of factors including tarmac turn-time savings, loss of revenue for the 80% of wheelchair users not traveling (and their families), cost to replace or repair damaged wheelchairs, legal fees associated with current airline wheelchair practices, negative viral posts/media related to wheelchair damage or mistreatment of people with reduced mobility, and more.

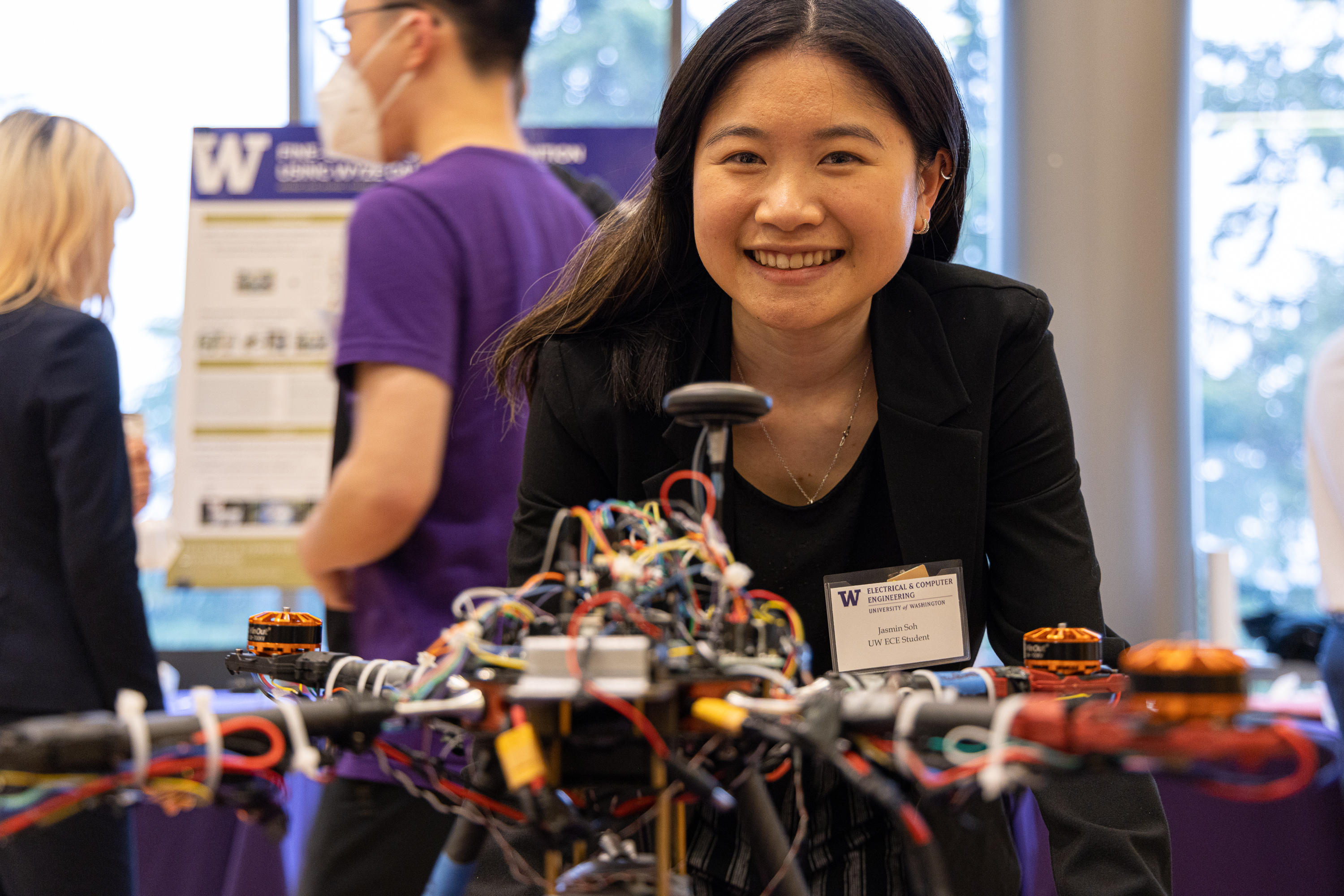

Amazon

Airframe Health Monitoring System

The student team worked to develop and demonstrate the capability and benefits of a health monitoring system for a UAS airframe. They used onboard sensors and flight data to determine airframe health, predict maintenance intervals and diagnose off nominal airframe behavior. The team examined the existing sensing capability of a drone to determine potential benefits of health monitoring, explored additional sensing capabilities and the added capability of a monitoring system, and down-selected and developed a system capable of tracking the performance of an airframe component through one lifecycle.

Amazon

Energy Efficient Wireless Systems and Sustainability

Sustainability has become a key factor in engineering and design of modern electronics. One of the major contributors of carbon impact is wireless devices, during the production of integrated circuits and usage of wireless communication over the lifecycle of the product. Amazon seeks to reduce the carbon footprint of its products and processes. This student team researched developments in energy-efficient wireless communication, summarize findings in and extensive report, and proposed alternative strategies for energy-efficient wireless communication and applications.

Amazon

Multi-Ship Mode Forecasting and Optimization

The student team worked to solve a regional transportation capacity planning problem. The modern fast shipping and supply chain framework has resulted in constant variation in shipping demands. Both short-term and long-term capacity planning require forecasting and optimization solutions. The student team created a tool that can take historical shipper demands as input and generate short term (4-weeks) and long-term (12-months) shipping volume forecast for Full Truckload (FTL), Less-Than-Truckload (LTL) or Small Parcel (SP) carriers. The output of the tool includes intuitive visuals that work for both operators and management teams.

ATS Automation

ATS Augmented Installation and Checkout

ATS is a building automation company that designs and installs solutions that control various systems in a building. The student team built an augmented reality application that can assist installers, electricians, and field technicians during the installation phase of projects in identifying the incoming and outgoing wires on a building automation system, BAS, or controller.

BigIdea Partners

Composite Hybrid Electric STOL Utility Aircraft

This student team developed a conceptual design of a composite hybrid electric STOL (short takeoff and landing) utility aircraft capable of replacing the DHC-2 DeHavilland Beaver in overall performance and functionality. The team conducted performance sizing, configuration trade studies, and conceptual design activities to develop the aircraft's overall configuration, internal details, and operating concept. Specific emphasis was placed on using modern materials (e.g. composites, 3D printing) and aerodynamics in conjunction with a hybrid electric propulsion system to drive down operating cost and improve operating performance over the reference vehicle.

BluePallet/Wisecube

Deep Learning Approach to Molecular Property Prediction

BluePallet was formed in 2020 through a merger between Velloci, a FinTech platform, and EchoSystem, a chemical marketplace founded in 2017. BluePallet was built with the support and advice of The National Association of Chemical Distributors (NACD) and its 400-plus members and affiliate companies and based on the platform created by BluePallet founder and CEO, Scott Barrows and now utilized by Ticketmaster, Live Nation, and the NFL. Wisecube is a team of veteran data scientists and engineers that focus on solutions for the Life Sciences Industry. They have been building and operating data driven products and platforms for many decades. They have taken their passion for data and have chosen to apply it in the life sciences domain where they can have a truly life changing impact. This ChemE DIRECT graduate student team will work to integrate the Chemprop library into a small molecule modeling platform, Dryad. This will involve three phases: PHASE 1: Build baseline models for a list of molecular properties. These will be neural network models for classification and regression. PHASE 2: Deploy the models to the Dryad. This will involve writing the code for taking a SMILES string and producing a prediction. PHASE 3: Experiment to improve the models. This phase is a stretch goal, but offers the opportunity to try novel modeling approaches to reach state-of-the-art performance. The datasets of the models to be built are QM8, QM9, ESOL, FreeSolv, Lipophilicity, PDBbind, PCBA, MUV, HIV, BBBP, Tox21, SIDER, and ClinTox.

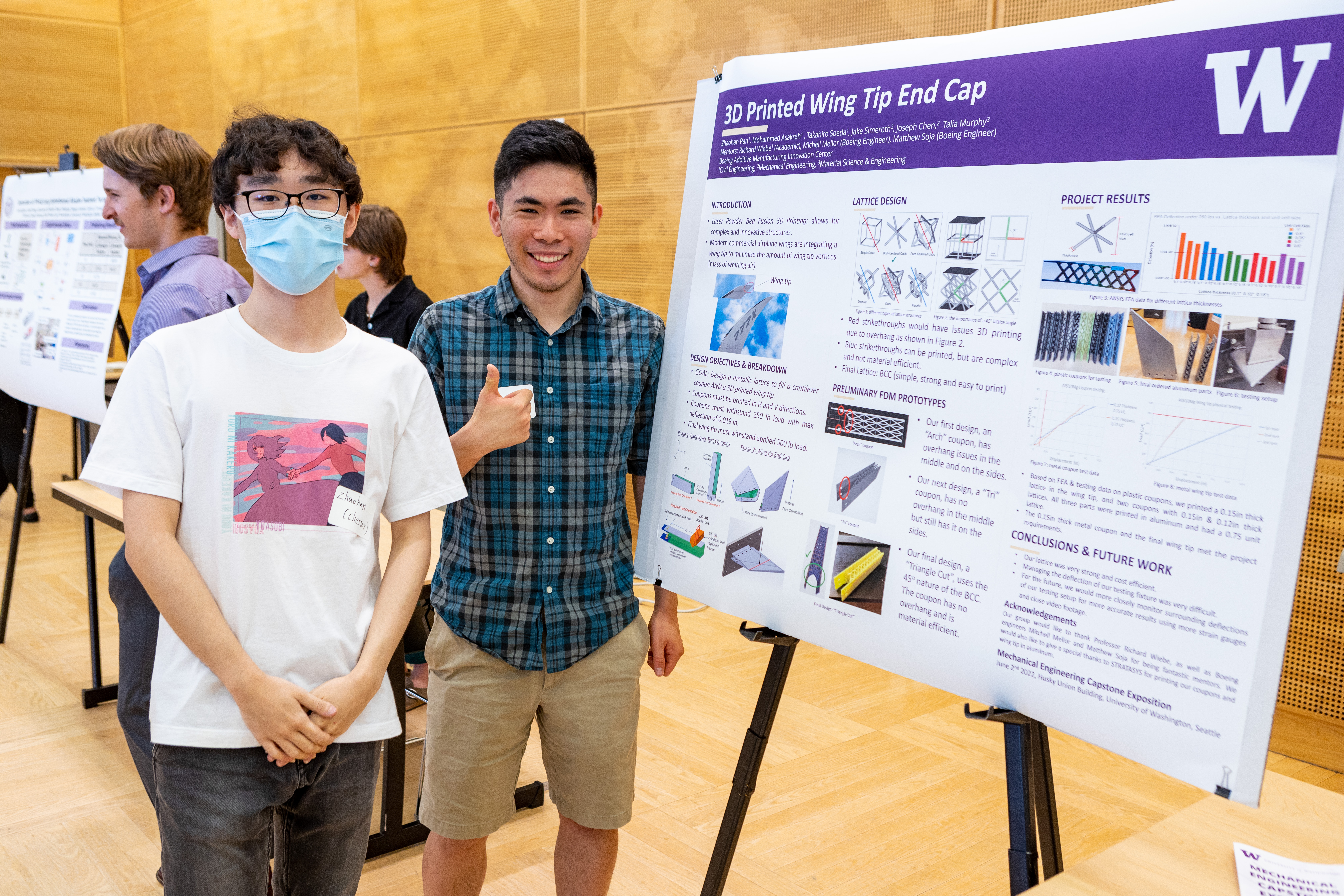

Boeing

3D Printed Wing Tip End Cap

Modern commercial aircraft wings often include winglets or rake tips to minimize wingtip vortices that cause drag. These tip designs have become very intricate and complex in order to achieve the maximum efficiency. These designs, in many cases, must be fabricated out of solid metal in order to achieve the required shape and stiffness with the limitations of traditional machining processes. This student team worked to design (with optimization for weight reduction and stiffness), print, and test a sub-scale lattice reinforced hollow wing tip end cap to replace a traditional machined wing tip, and provided Boeing with an evaluation of tier findings and recommendation for suitable lattice structure designs.

Boeing

Additive Manufacturing Data Analytics, Process to Performance Analysis

Additive manufacturing (AM) is a digital process that provides critical information across the entire process lifecycle from product definition, manufacturing, test/inspection and final acceptance. This information is comprised of large spatial and temporal data sets that provide insights to the quality of the final manufactured part. These data sets currently reside on disparate systems which can limit correlation and advancement of AM process understanding and insights. There is a desire to integrate these data sets into a "super set" of data that is registered and fused together using data consolidation and visualization techniques. With the data integrated, there is the opportunity to apply new data analysis techniques to infer relationships between in process, post process and performance data. The student team worked to enhance data analytics applied to existing UW data sets through the development of new software packages that enable large AM data sets to be integrated.

Boeing

AM Powder Bed Fusion Part Porosity Sources

Additive manufacturing (3D printing) with metals has the potential for significant weight savings in aerospace applications, along with numerous other advantages. To realize these advantages, the sources and amounts of variability in component strength and fatigue properties must be well understood. A “round robin” study started at UW last year focused on intra-build, intra-machine, and inter-machine variation using a EOS M290 printer to laser-sinter titanium components. Based on preliminary results, the argon gas pressure variation contributed to poor part porosity and needs to be explored further. This student team will leverage the existing UW Round Robin study to design the experiments searching for the optical gas pressure for the production, and use data science methods, statistical analysis, and data visualization for the results to provide recommendations on design outcomes. ME prerequisites: None

Related News

Fri, 09/20/2024 | UW Civil & Environmental Engineering

Smarter irrigation for a greener UW

A new project combines satellite data with ground sensors to conserve water and create a more sustainable campus environment.

Mon, 09/09/2024 | UW Mechanical Engineering

Testing an in-home mobility system

Through innovative capstone projects, engineering students worked with community members on an adaptable mobility system.

Mon, 08/19/2024 | UW Mechanical Engineering

Students strive to ensure accurate AED shock dosage

ShockSafe, developed by students with the help of mentors from Philips and Engineering Innovation in Health (EIH), can distinguish between children and adults during cardiac arrest emergencies.

Wed, 08/07/2024 | Snohomish County News

Snohomish County, University of Washington partnership boosts efficiency in enterprise scanning center

UW Industrial and Systems Engineering Capstone Project set to save Snohomish County over $40,000 annually.