Goodwill

Evergreen Goodwill Production Efficiency: Level 2

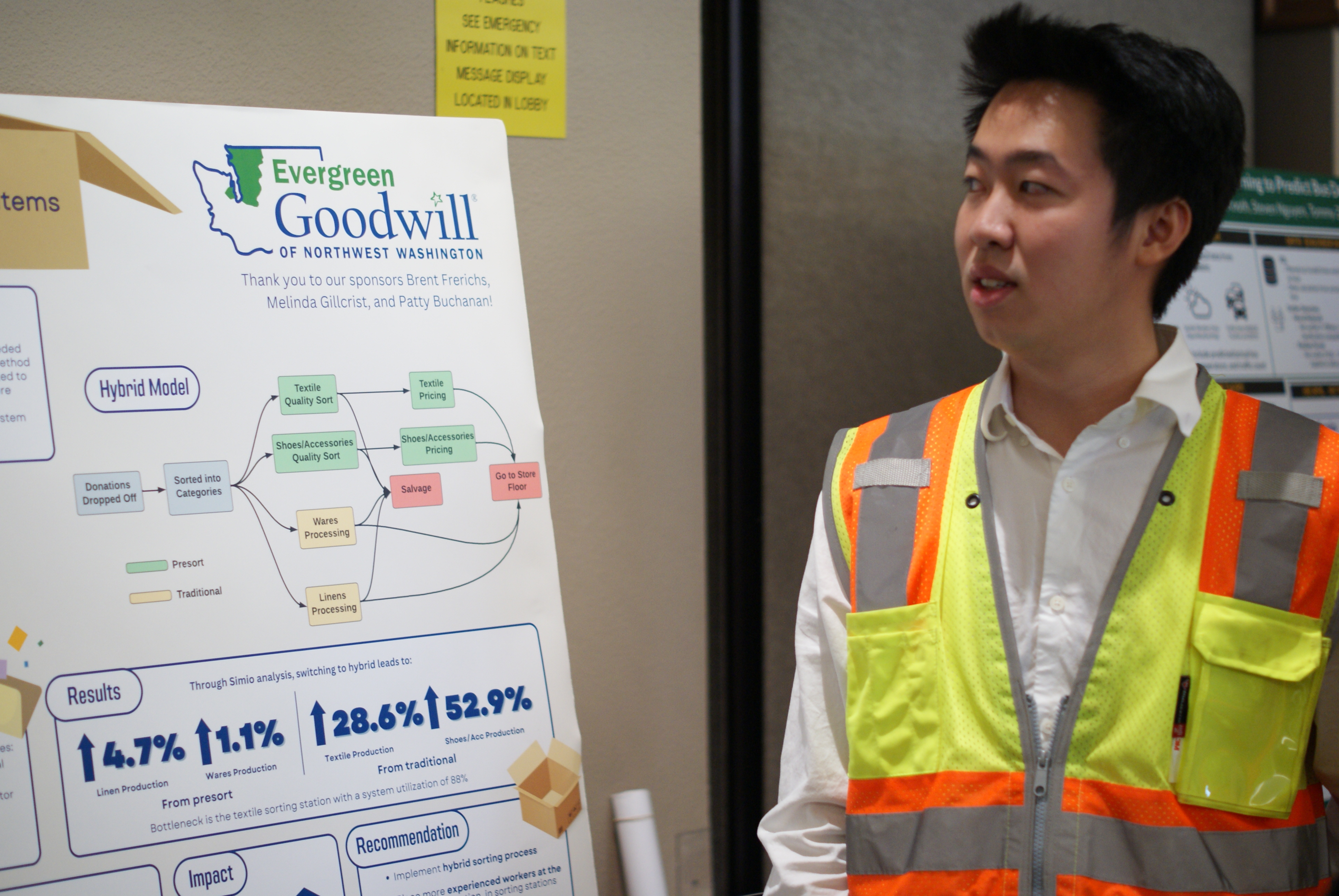

This is a continuation of the Capstone projected initiated in the '21-'22 school year. The 21/22 student team addressed Evergreen Goodwill's production process (the sorting and pricing of donated clothes) seeking greater efficiencies through innovation and arrived at a pre-sort solution that could result in significant monetary savings and a more efficient use of resources. For '22-'23 Evergreen Goodwill wanted the student team to work to build upon that premise and refine it by visiting these questions: is the conclusion/recommendation correct? Is the suggested process the most efficacious? Are the alternatives that have not been addressed that would result in a greater use of resources? Since Evergreen Goodwill anticipated being in a pre-sort mood in some stores (using the recommendations of the previous group) they wanted this year's student team to work to address challenges and opportunities within the process. One possible addition was that Evergreen Goodwill may introduce a new, more sophisticated way of classing their merchandise at the point of production (for instance, instead of just "women's apparel" they would have " dresses," "pants," "skirts" etc. Evergreen Goodwill also wanted this year's student team to work to explore how this new addition now ties into a pre-sort process? This student team worked to accomplish the following outcomes: - Time savings - Monetary savings - Greater enjoyment of work - Greater fluidity of donated resources; making the best possible use of everything we are given.

Faculty Adviser

Patty Buchanan,

Industrial & Systems Engineering

Students

Anthony Liem

Jessica Hwee

John O'Kane

Mckenna Dawson

Related News

Fri, 09/20/2024 | UW Civil & Environmental Engineering

Smarter irrigation for a greener UW

A new project combines satellite data with ground sensors to conserve water and create a more sustainable campus environment.

Mon, 09/09/2024 | UW Mechanical Engineering

Testing an in-home mobility system

Through innovative capstone projects, engineering students worked with community members on an adaptable mobility system.

Mon, 08/19/2024 | UW Mechanical Engineering

Students strive to ensure accurate AED shock dosage

ShockSafe, developed by students with the help of mentors from Philips and Engineering Innovation in Health (EIH), can distinguish between children and adults during cardiac arrest emergencies.

Wed, 08/07/2024 | Snohomish County News

Snohomish County, University of Washington partnership boosts efficiency in enterprise scanning center

UW Industrial and Systems Engineering Capstone Project set to save Snohomish County over $40,000 annually.