adidas

Natural Language Inputs in 3D Printed Footwear Components

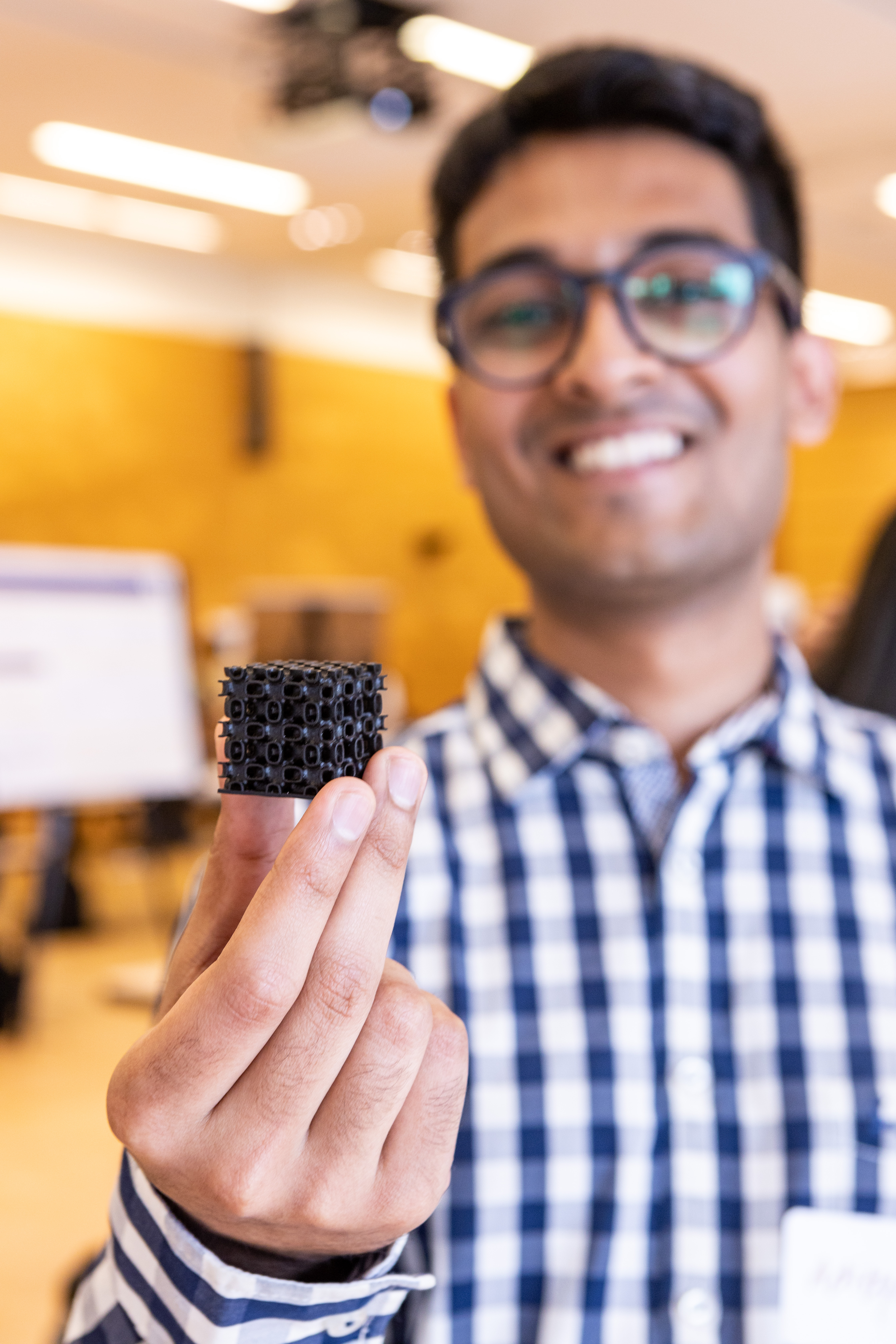

Last year, a capstone team worked with adidas on their line of 3D printed mid-soles. This year's team continued their work to create an understanding of common language used by running footwear consumers and translate this language into the engineering space. The team gathered information about language use from athlete-consumers directly and linked this language to commonly 'found' objects (i.e.: sponges, foam rollers, bouncy balls). The team then designed and printed sample pucks around these consumer findings that are able to be stepped onto to mimic the midsole of a shoe. The capstone team used a software program to change aspects of the shoe, then printed (using UW's Carbon DLS printer) and tested the designs.

Faculty Adviser

Jeffrey Lipton,

Director of the Center for Digital Fabrication (DFab),

Mechanical Engineering

Students

Aditya Patil

Atharv Wairagade

Kelly Chu

Kimberly Nickerson

Tianyi Ren

Related News

Fri, 09/20/2024 | UW Civil & Environmental Engineering

Smarter irrigation for a greener UW

A new project combines satellite data with ground sensors to conserve water and create a more sustainable campus environment.

Mon, 09/09/2024 | UW Mechanical Engineering

Testing an in-home mobility system

Through innovative capstone projects, engineering students worked with community members on an adaptable mobility system.

Mon, 08/19/2024 | UW Mechanical Engineering

Students strive to ensure accurate AED shock dosage

ShockSafe, developed by students with the help of mentors from Philips and Engineering Innovation in Health (EIH), can distinguish between children and adults during cardiac arrest emergencies.

Wed, 08/07/2024 | Snohomish County News

Snohomish County, University of Washington partnership boosts efficiency in enterprise scanning center

UW Industrial and Systems Engineering Capstone Project set to save Snohomish County over $40,000 annually.