Latécoère

Oldham Joint With Hyper Elastic Contact Area

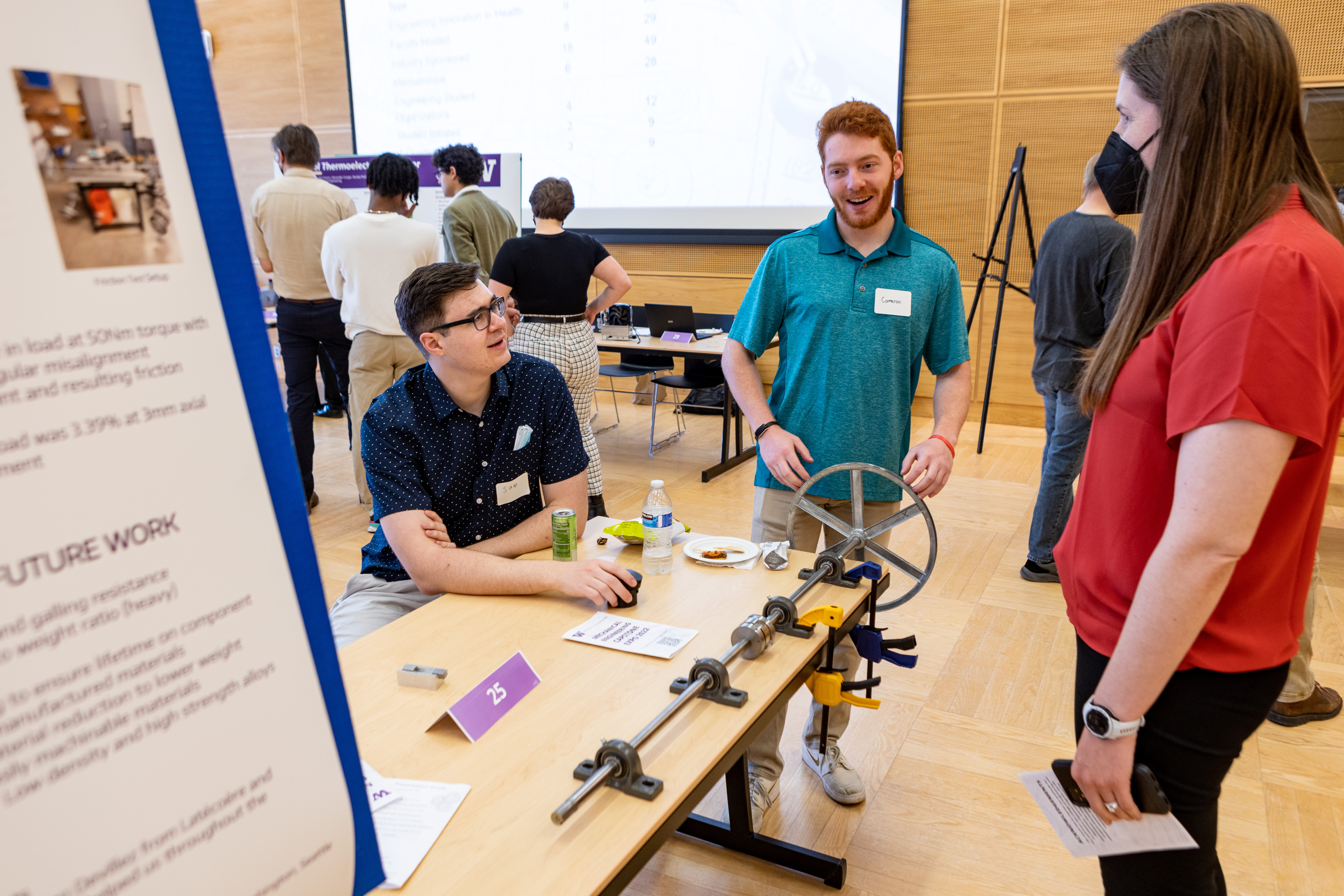

In aircraft door design, a challenge is that typical loads are quite low compared to sizing loads. Oldham joints are currently used in several doors because they simplify the interface between mechanism and structure. However, oldham joints can still have issues with high contact pressure, friction, and wear and tear. Significant weight and cost reductions may be possible with a design that could better accommodate those maximum loads and address the issues with current oldham joints using hyperelastic materials. The student team worked to identify a hyperelastic material able to meet Latécoère's door mechanism requirement and create a design and establish analysis to show compliance. Finally, they created a prototype for manufacture and testing.

Faculty Adviser

Eli Patten,

ME Capstone Director,

Mechanical Engineering

Students

Cameron Masters

Laura Doumaux

Noah Adler

Sam Moorhouse-McNerney

Related News

Fri, 09/20/2024 | UW Civil & Environmental Engineering

Smarter irrigation for a greener UW

A new project combines satellite data with ground sensors to conserve water and create a more sustainable campus environment.

Mon, 09/09/2024 | UW Mechanical Engineering

Testing an in-home mobility system

Through innovative capstone projects, engineering students worked with community members on an adaptable mobility system.

Mon, 08/19/2024 | UW Mechanical Engineering

Students strive to ensure accurate AED shock dosage

ShockSafe, developed by students with the help of mentors from Philips and Engineering Innovation in Health (EIH), can distinguish between children and adults during cardiac arrest emergencies.

Wed, 08/07/2024 | Snohomish County News

Snohomish County, University of Washington partnership boosts efficiency in enterprise scanning center

UW Industrial and Systems Engineering Capstone Project set to save Snohomish County over $40,000 annually.