Industry-Sponsored Student Capstone Projects

2021/2022

In the 2021/22 academic year the industry capstone program was supported by 62 sponsors and 95 real-world projects. Over four hundred students from across the College of Engineering participated. Scroll down to learn more about each project.

NASA Jet Propulsion Laboratory

Autonomous Exploration through Heterogeneous Robotic Collaboration

This student team worked to develop and demonstrate software algorithms capable of supporting collaborative heterogeneous multi-agent autonomous exploration of Mars' physical environment. The students' proposed system comprises one drone and one rover. While the drone can provide a broader view of the area, the rover can complement with detailed information for a smaller surrounding area. With each robot free to move independently, together they can perform distributed measurements that would be nearly impossible for a single robot to achieve.

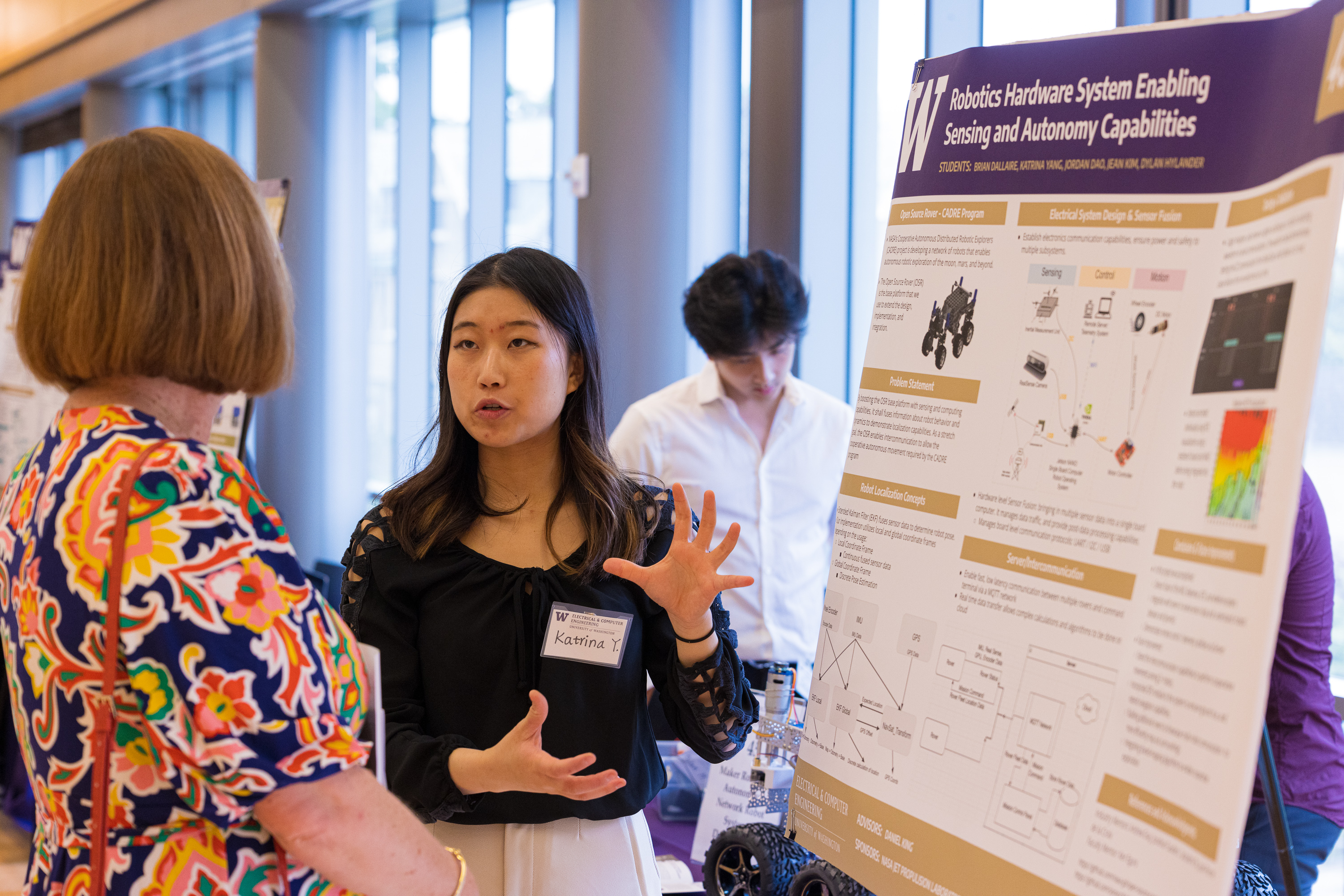

NASA Jet Propulsion Laboratory

Maker Robots for Autonomous Network Robot Systems Development

NASA's Cooperative Autonomous Distributed Robotic Explorers (CADRE) project is developing a network of mobile robots with the goal of cooperative autonomous exploration of the Moon, Mars, and beyond. Through the system design and collaboration of electrical hardware and robotics perceptions, the student team designed, built, and integrated a platform of software and devices in the form of an Open-Source Rover. The rover actively provides real-time data from an Inertial Measurement Unit (IMU), GPS, RealSense Camera, and wheel speed sensors using Wi-Fi to store valuable information and navigate autonomously.

National Oceanic and Atmospheric Administration (NOAA)

Intertidal Sensor Array for Monitoring Ocean Change Stressors in Oyster Farms

This student team worked to develop an intertidal sensor array and remote data management system that could be deployed and used by shellfish growers, informing farmers of appropriate management strategies through measurement and analysis of water quality parameters such as pH and temperature. This sensor array integrates data management, battery power, and wireless communication in a robust package using off-the-shelf components, designed to function in harsh environments.

Nintex

Intelligent Data Wizard

Nintex is building the next general low and no-code intelligent platforms to help companies in storing and managing their data. The student team worked to extend the existing Nintex platform by enabling customers to generate schemas capable of a wide range of data type conversion. The team built an intelligent data advisor with a universal intermediate model, which is more efficient and widely compatible compared to regular format converters.

Novo Nordisk

Data Insights Engine Tool

Novo Nordisk is working to create a data insights engine that allows the company to incorporate predictive and prescriptive insights into their innovation process. The student team worked to design and create the UI/UX for this tool for internal Novo Nordisk teams to interact with the data, and identify and understand previously undefined personas that can then be provided with novel and innovative healthcare solutions.

Novo Nordisk

Neuropathy Patient Assistant

The student team created the Neuropathy Patient Assistant App, which provides a user-friendly dashboard of the patient's glucose levels and their activities. Given that neuropathy patients undergo immense pain in the limbs, the app provides recommendations to alleviate pain in hands and feet through exercises. The app also provides timely recommendations to patients to maintain a healthy lifestyle and keep diabetes under control.

Novo Nordisk

Smart Home Sensor for Diabetic Foot Ulcerations

One-third of diabetics will experience diabetic foot ulcerations (DFUs) which can significantly diminish quality of life and even lead to amputations if not caught early. In order to help reduce the severity of DFUs, the student team developed a system that uses a combination of sensors and a deep learning model to analyze the data and foot images. This information was incorporated into a smartphone app where the user can take daily surveys to evaluate the status of their feet, view past records of their feet, and receive recommendations for a course of action.

Nutanix

Security Attach and Defense Reasoning Framework

The student team developed and tested a first-order logic expert system that can use existing knowledge, acquire new knowledge from user inputs, and provide answers to questions using known facts via deduction and explanations to the answers that it provides. The system will be used to model various cybersecurity domains and identify the potential pathways to accessing sensitive data.

PACCAR

BOM Wire Tracer

Harness drawings show the schematic and layout of the electrical wires used in PACCAR’s vehicles. Because there are several harness files not within the same system, it requires a lot of hand tracing to analyze the harness in the circuit. To solve the issue, this student team worked to design a software that takes in multiple BOM (bill of materials) and fuse maps to auto-trace and analyze the risk level of each circuit in the BOM.

PACCAR

Compact AM Broadcast Band Radiating Antenna

The student team worked to design and construct a portable, self supporting, compact radiating antenna that will efficiently cover the AM broadcast band and produce E fields at greater magnitudes than the electrically short dipole antenna currently being used. The compact radiating antenna will be used as part of a testing practice utilized by PACCAR to evaluate on-vehicle sources of electromagnetic noise which may interfere with the radio receivers in the vehicle.

PACCAR

Defining DE-Sulfation SCR Behavior

Diesel engine aftertreatment systems architecture will change as a result of upcoming stringent Ultra Low NOx emission regulations in the US. A close coupled (downstream turbine) SCR is under investigation but is exposed to Sulphur from the fuel and oil reactants. This student team worked to define accurate physics / reaction rate-based models to simulate Sulphur loading and release behavior as a function of key system parameters such as engine flow, exhaust temperature and exhaust composition. The team produced detailed design and control rules to implement SCR in the proposed configuration without losing efficiency over time due to Sulphur poisoning.

PACCAR

Fabrication Shop Layout Optimization

PACCAR’s Technical Centers in Europe and North America are equipped with state-of-the-art product development and validation capabilities and staffed with experts in powertrain and vehicle development. The advanced engineering tools in the technical centers, including 3-D prototype machines, road simulators, and supercomputers, are utilized to innovate and accelerate the launch of new products. The student team looked at existing fabrication shop layout and equipment to assess workflow needs, current infrastructure, equipment space requirements, storage solutions, foot traffic and more to provide a safe and efficient lab area and increase margin within existing footprint for the addition of new machinery and improved throughout. They then created an ideal floorplan with existing equipment - and room for future technologies- with the constraints of a new fab shop, as part of the proposed future facility expansion.

PACCAR

MD and HD Vehicle Range Estimation Tool

PACCAR is working to develop multiple new powertrain architectures, such as battery, fuel cell, and diesel hybrid, for their medium duty (MD) and heavy duty (HD) trucks. With this development, there is a need to optimize component sizing and select the right configuration for different real-world vehicle applications. A modeling tool based on Matlab Simulink is currently used to simulate existing diesel-battery hybrid vehicles. This student team worked to incorporate new powertrain technologies and a generic optimization algorithm into this tool to determine required component sizing such as batteries, e-motors, etc. The tool can evaluate and optimize powertrains based on different drive-cycles and performance requirements with the use of optimization algorithms and machine learning to reduce computational costs.

PACCAR

New Stress & Strain Durability Fixture

To reduce the weight and improve the fuel economy of big rigs, and reduce costs, the long term durability of thermoplastics and adhesives needs to be tested under both constant and dynamic stress conditions and subject to high and low temperatures, salt fog exposure, high humidity exposure, and water submersion. A test fixture that could efficiently test a large number of samples under these wide-ranging conditions could greatly accelerate their development and adoption. A previous capstone team developed a test fixture capable of holding a chain of many test specimens in both constant and dynamic stress conditions. This student team redesigned some specific subsystems of the fixture to improve the overall performance and capability, including as using pneumatic actuators instead of electric stepper motors and load washers instead of a custom-made load cell. The team also used the fixture to test adhesive specimens bonded to a stainless steel substrate to determine if the alternatives can provide increased service life.

PACCAR

Robotic Arm for Automating Tester Connection

Robotic automation is a flourishing process that PACCAR wants to add to its Manufacturing Support Team. An automatic solution will free up test operators to use their time more efficiently and reduce the time required to test each dash, saving time and money for the plant and the company. The student team worked to incorporate a Kawasaki robotic arm capable of accurately connecting a plate containing multiple cable connectors to the plugs of the rear of a semi-truck dashboard.

Related News

Fri, 09/20/2024 | UW Civil & Environmental Engineering

Smarter irrigation for a greener UW

A new project combines satellite data with ground sensors to conserve water and create a more sustainable campus environment.

Mon, 09/09/2024 | UW Mechanical Engineering

Testing an in-home mobility system

Through innovative capstone projects, engineering students worked with community members on an adaptable mobility system.

Mon, 08/19/2024 | UW Mechanical Engineering

Students strive to ensure accurate AED shock dosage

ShockSafe, developed by students with the help of mentors from Philips and Engineering Innovation in Health (EIH), can distinguish between children and adults during cardiac arrest emergencies.

Wed, 08/07/2024 | Snohomish County News

Snohomish County, University of Washington partnership boosts efficiency in enterprise scanning center

UW Industrial and Systems Engineering Capstone Project set to save Snohomish County over $40,000 annually.