Driven to advance vehicle electrification

Engineering research leads the next wave of electric vehicle technologies

By: Brooke Fisher

Photos: Dennis Wise/University of Washington and UW researchers

When it comes to developing the next generation electric vehicle (EV) technologies, UW engineering researchers are unstoppable. Their collective research, together with initiatives underway throughout the state, positions Washington to be a leader in this truly electrifying area.

“The goal is for Washington state to be a leader in EV technologies and battery manufacturing and research,” says Jihui Yang, vice dean of the College of Engineering. “Our UW researchers are working on everything from identifying new battery materials and chemistries to improving power transfer and workforce development.”

UW engineering research, along with newly established manufacturing facilities and raw materials available in Washington, enables the state to be a hub — especially for next-generation battery development. Two new EV battery manufacturing facilities, Sila and Group14 Technologies, are establishing factories in Moses Lake, funded with $100 million each from the U.S. Department of Energy. In addition, Washington is one of the richest states in biomass, a promising material for EV battery production. Byproducts from sources such as responsibly harvested timber can be turned into hard carbon and graphite, and used for negative electrodes.

“So whatever battery composition, from lithium-ion to sodium-ion, there’s a way for us to explore renewable ways to make future batteries,” Yang explains. “We can actively and effectively reduce the carbon footprint by converting biomass into a useful energy source.”

Below, we highlight four projects underway across the College of Engineering that are advancing EV innovation.

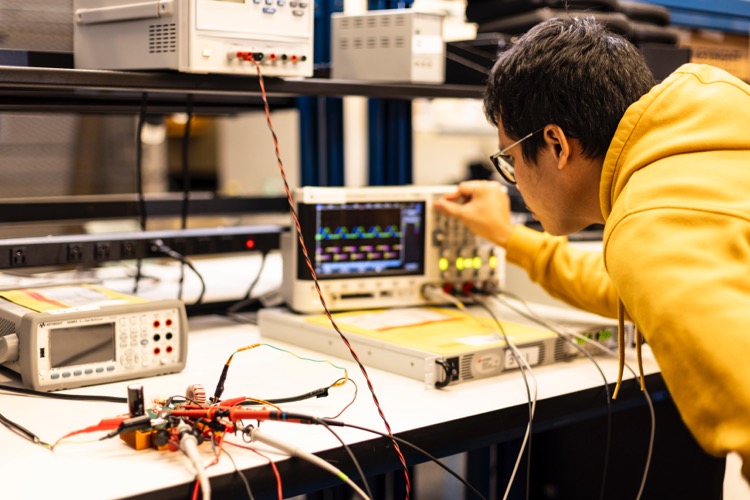

Left: Electrical and computer engineering graduate student Ghovindo Surya turns the knob on an oscilloscope to test the electrical currents received by the power circuit. Top right: Connecting voltage probes to a circuit board. Bottom right: A computer model shows a power circuit designed to receive electrical energy at high frequencies.

Leading the charge to enhance power transfer

Imagine rolling into a parking spot and your EV automatically begins to charge, quickly and without cables, thanks to a compact charging station on the ground. Jungwon Choi, an assistant professor of electrical and computer engineering, can do more than envision it — she’s developing the technology.

“Charging time is a barrier for people buying EVs,” Choi says. “I’m interested in how we can make more efficient power circuits to charge the battery in electric vehicles.”

To enhance EV charging, Choi is involved in research on many levels. In addition to advancing the design of spiral coils for high-frequency wireless charging — in which power is transmitted electromagnetically between coils located in a vehicle and charging station — her primary research focuses on designing power circuits that can receive electrical currents at high frequencies from a charging source and transfer the energy to the battery.

“We want to have high efficiency,” Choi explains. “When we have 100% power at input and the battery receives only 80% power, then it’s lost as heat. It’s harmful for the system and energy is lost.”

A unique feature of power converters that Choi’s team is working to advance is the two-way flow of energy, which would enable EV batteries to store energy that could be utilized as backup power.

“In an emergency situation, or in case of a blackout, we could draw power from a vehicle into a house,” Choi says.

Civil and environmental engineering graduate student Rubina Singh stands next to an EV charging station.

Plugging in to prospective consumers

There’s one potential roadblock to EV ownership that civil and environmental engineering researchers are exploring: the unreliability of public charging stations.

“The number one problem now is not lack of charging stations, but reliable stations,” says Don MacKenzie, Allan & Inger Osberg Endowed Professor in civil and environmental engineering. “Public fast-charging stations are notoriously unreliable. Sometimes the hardware is broken, vandalized or switched off, and payment systems commonly fail.”

Despite the fact that the majority of EV owners charge their vehicle at home, the ability to utilize public stations is an important consideration, especially for longer trips. The UW researchers are specifically investigating how the unreliability of public charging stations may influence the second wave of EV owners.

“As you move from the early adopters and innovators to the mainstream market, you move to a set of customers who are much less tolerant,” explains MacKenzie. “The early adopters put up with a lot of inconvenience that other people have no patience for.”

The project informs the work of the ChargeX consortium, tasked with improving public charging infrastructure in the country by 2025. Led by Idaho National Laboratory, the consortium was established by the U.S. Joint Office of Energy and Transportation to bring together industry members and academic institutions. To better understand the preferences of people who don’t yet own EVs, the UW researchers recently distributed a nationwide survey.

“We will ask people to imagine different experiences, such as a world where public chargers are terrible and don’t work, and then a world where public chargers work perfectly,” explains graduate student Rubina Singh.

Left: At the Washington Clean Energy Testbeds, Shijing Sun, assistant professor of mechanical engineering, and her students review data pertaining to battery cycling tests. Top right: Lithium-ion batteries used for a battery cycling test, which evaluates batteries to determine the number of times they can be used before they begin to degrade. Bottom right: A battery is inserted into a battery testing channel.

A healthy plan for battery maintenance

Developing a roadmap for how to best manage and enhance the health of EV batteries is the objective of a team of mechanical engineering researchers.

“Battery health is an important concept that relates to the long-term costs of batteries and their safety,” explains Shijing Sun, an assistant professor of mechanical engineering who was a senior research scientist at the Toyota Research Institute before joining the UW last year. “We need to have maintenance plans for the increasing number of EVs on the road.”

Once batteries are installed in EVs, it’s important to have reliable systems in place to monitor battery health, Sun says. In addition to planning ahead for the replacement of aged batteries, managing the overall battery health can also help extend the life of the battery by advising drivers in certain conditions to seek maintenance.

To develop highly predictive models, Sun’s research employs artificial intelligence to process large and complex datasets. Together with her students, she conducts tests at the Washington Clean Energy Testbeds, part of the Clean Energy Institute. They analyze battery charge and discharge behavior to investigate factors that affect performance, such as the frequency of charging and the environment — for example, a battery in Arizona would perform differently than one in Alaska. Human behavior is also a factor, as aggressive driving and rapid braking can drain the battery.

“These are all interconnected and difficult to decouple,” Sun explains. “Better understanding how the battery behaves today and identifying limitations will also guide us to explore new ideas for the next generation of batteries.”

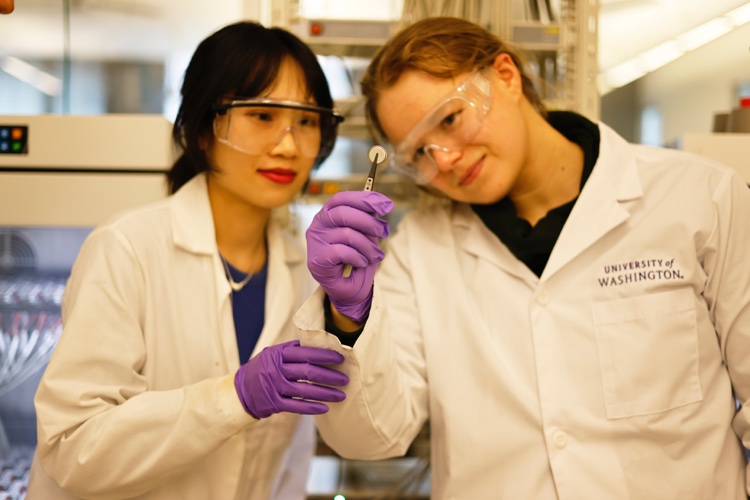

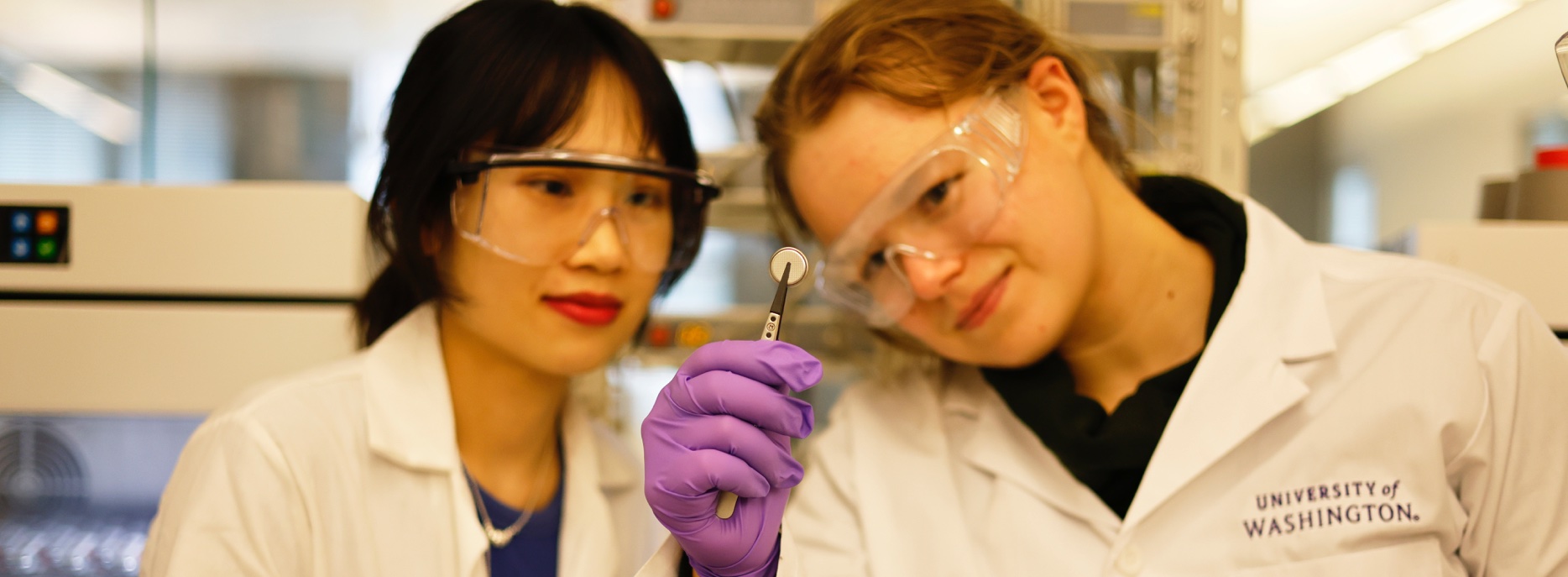

Materials science and engineering graduate students Bella Wu and Julia White, from left, look at a lithium-metal coin cell.

Next up: The next generation battery

An EV battery that needs to be charged much less frequently than stopping at a gas station is one goal of UW engineering faculty who are collectively working toward developing the next generation EV battery materials and technologies. Other objectives include reducing the cost and extending the lifespan of EV batteries.

UW researchers Corie Cobb, a professor of mechanical engineering, and Jun Liu, a professor of materials science and engineering and of chemical engineering, are currently investigating how to extend the cycle life of lithium-ion batteries used in EVs. The cycle life is the number of times a battery can be charged and discharged before it begins to degrade, and the researchers — both Washington Research Foundation Innovation Professors in Clean Energy — are working with Pacific Northwest National Laboratory’s (PNNL) Cathode-Electrolyte Interphase Consortium, supported by the U.S. Department of Energy’s (DOE) Vehicle Technologies Office.

UW researchers also play an important role in the Innovation Center for Battery500 Consortium by advancing a type of battery that shows great promise: lithium-metal batteries, which can store twice as much energy in the same amount of space as lithium-ion batteries. Led by PNNL and joined by Brookhaven National Laboratory, Idaho National Laboratory, SLAC National Accelerator Laboratory, General Motors, UW and eight other universities, Battery500 Consortium is a national program supported by the DOE Vehicle Technologies Office to develop next generation EV batteries.

“Our first goal is to make fundamental breakthroughs in materials science and engineering, and in chemistry, for batteries,” says Liu, who directs the Battery500 Consortium and is a Battelle Fellow at PNNL. “Our second goal is to deliver a real battery to industry.”

Workforce development

Advancing education and workforce training in battery materials manufacturing is a priority of UW engineering faculty. In addition to developing courses and internships with national labs and industry, faculty are working with the Clean Energy Institute to design battery certificate programs and hands-on classes on clean energy. Liu is leading this effort with Eleftheria Roumeli, assistant professor of materials science and engineering, John Kramlich, professor of mechanical engineering, and in collaboration with the DOE, PNNL, industry, local community colleges and high schools.

Students shift gears

Getting the next generation of engineers up to speed on the latest EV technologies is important for workforce development. In addition to coursework, a growing number of engineering clubs, as well as capstone projects, are focused on advancing electrification.

- Clubs and teams: Students are converting a diesel truck from PACCAR into a battery electric truck with UW E-Truck, and designing and building both a zero-emission motorcycle with Washington Superbike and electric race cars with Formula Motorsports.

- Industry capstone projects: Last year, Ford Motor Company sponsored a project that tasked students with creating the ideal EV charging experience. This year, a team of students is working to reduce the cost of infrastructure for charging stations in a project funded by McKinstry.